PREHEATER TOWER

Achieve capacity and energy benefits in your preheater.

The design of the preheater system is a major factor for efficient cement production. Its design and complexity have evolved rapidly thanks to growing production volumes and increasing energy costs.

Today’s dry process kilns, coupled to multiple-stage preheater systems, offer 20 times more capacity than similarly sized wet-process kilns. The thermal efficiency and capacity of a modern cement-making operation is very high – but can be even higher with the right refractory solutions.

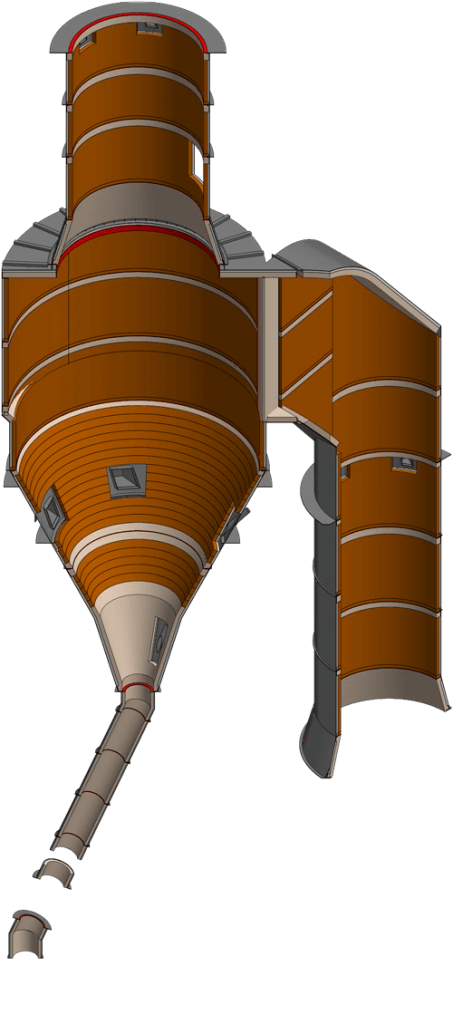

In this section, we deal specifically with the following areas of the preheater tower:

Cyclone – Gas ducts – Meal pipes

Click to enlarge

The objective of the cyclone system is to support greater thermal efficiency, and greater kiln capacity. Höganäs Borgestad has developed refractory solutions that allows you to:

- Operate under increasingly high temperatures

- Withstand the chemical attack of alkalis, chlorine, sulfur and transition metals

- Meet the construction requirements of ever-larger cyclone units

- Provide the smooth, non-wetting surfaces that support optimal airflow and reduce or eliminate build-ups

Our refractory solutions are listed on the table below:

| Area / Temperature (°C) | Processing Conditions | Monolithic solution | Brick solution | Energy Saving brick solution |

|---|---|---|---|---|

| Cyclone / Gas Ducts Upper stages | Very mild abrasion No Chemical attack No Build-up | HÖGANÄS CAST CC 30 HÖGANÄS CAST CC 40 | Viking 220/Viking 330 Insulation SUPER 1100 E/Slabs HIPOR 450/brick | Cyclone stage 1/external shell T=70°C Viking 330 (114mm) Insulation HÖGANÄS INSUL 450/brick (38mm) Cyclone stage 2/external shell T=83°C Viking 330 (114mm) Insulation HÖGANÄS INSUL 450/brick (50mm) |

| Mid stage 600-800°C | Abrasion Mild Chemical attack | HÖGANÄS CAST LC 40 AR | Viking 220/Viking330 Insulation SUPER 1100 E/slabs HIPOR 450/brick | Cyclone stage 3/external shell T=93°C Viking 330 (114mm) Insulation HÖGANÄS INSUL 450/brick (64mm) Cyclone stage 4/external shell T=101°C Viking 330 (114mm) Insulation HÖGANÄS INSUL 450/brick (76mm) |

| Cyclone / Gas Ducts Lower stages 800 – 1000°C | Abrasion Alkali attack Build-up High temperature | HÖGANÄS CAST /GUN LC 50 AR HÖGANÄS CAST /GUN LC S10 (WITH AF) Insulation HÖGANÄS INSUL CC 1,5L | Viking 330 Severe conditions Alsic 500 Insulation SUPER 1100 E/slabs HIPOR 450/brick | Cyclone stage 5/external shell T=109°C Viking 330 (114mm) Insulation HÖGANÄS INSUL 450/brick (76mm) Severe conditions Alsic 500 (114mm) Insulation HÖGANÄS INSUL 450/brick (76mm) |

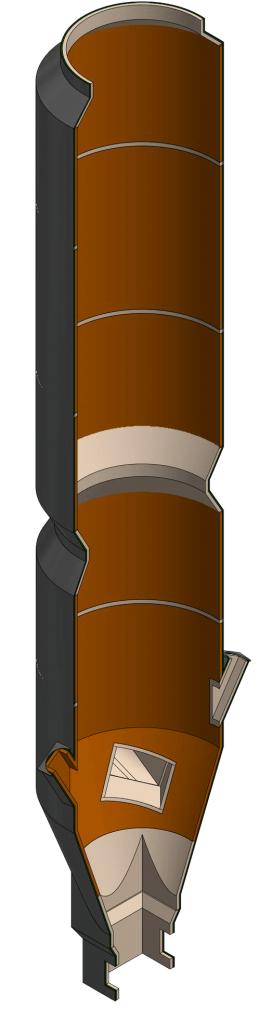

Calciner – Riser duct

Click to enlarge

Due to higher operating temperature, chemical attack is a more severe problem in the calciner than in the cyclones. High refractoriness and good resistance to thermal shock are also necessary, especially around the burner blocks.

In the lower, hotter part of the preheater system, chemical influences are the cause and can affect both straight and curved duct sections. Riser duct connected to calciner suffers often from build-up problems. In riser ducts connected to cyclones, build-ups are usually caused by a venturi effect. This occurs mostly in the curved sections of the duct. The closer the duct is to the ’hot’ end of the preheater system, the greater the risk of alkali penetration and refractory spalling. Where alkalis have penetrated to a depth of 20-30 mm, the refractory can expand 10 times more than normal, causing spalling. If this process is allowed to continue, the wall could collapse. To keep alkaline vapor from condensing, the amount of insulation should be reduced.

Our refractory solutions are listed on the table below:

| Area / Temperature (°C) | Processing Conditions | Monolithic solution | Brick solution | Energy Saving brick solution |

|---|---|---|---|---|

| High temperature 800- 1200°C | Alkali corrosion and infiltration Thermal shock High temperature | HÖGANÄS CAST /GUN LC 50 AR Severe Conditions HÖGANÄS CAST LC 60 AR HÖGANÄS CAST LC 75 AR HÖGANÄS CAST/GUN LC S10 Insulation HÖGANÄS INSUL CC 1,5L | Viking 330 Alex (hot zone calciner) Severe conditions/build ups Alsic 500(Riser duct) Insulation HÖGANÄS INSUL M E/brick HIPOR 450/brick Super 1100E | Viking 330 (230-300mm) Severe conditions Alsic 500(Riser duct/combustion chamber 230-300mm) Silox60(TAD) Insulation Insulation 1: Porosil 23/brick Insulation 2: HÖGANÄS INSUL 450/brick |

| Normal temperature 400- 800°C | Mild abrasion | HÖGANÄS CAST CC 30 HÖGANÄS CAST CC 40 | Same as above | Same as above |

Get installation instructions direct in your mobile phone, together with product and safety data for all Höganäs Borgestad monolithic products

Get installation instructions direct in your mobile phone, together with product and safety data for all Höganäs Borgestad monolithic products

Find us on social media